News classification

Contact us

- Add: ChanFu Dong Road,XiaoBian Village, ChangAn Town,DongGuan City,GuangDong,China

- Tel: +8613652508770(Jerry )

- Fax: 0769-23094426

- Email: [email protected]

How long is the life of a magnetic connector?

How long is the life of a magnetic connector?

Magnetic connector is an electronic connector that uses magnetic force to achieve automatic docking and stable connection. It is widely used in consumer electronics, medical equipment, industrial equipment and other fields. It is popular for its convenient operation, automatic adsorption, fool-proof design and high safety of use. In daily life, such as the MagSafe interface of Apple's early MacBook, the charging interface of smart bracelets, and some data transmission interfaces, all adopt the design of magnetic connector. So, how long is the life of this type of connector? What are the factors that affect the life? The following will discuss in detail the structure and working principle of the magnetic connector, the main factors affecting the life, industry standards, application case analysis and methods to extend the service life, so as to fully answer the service life of the magnetic connector.

1. Structure and working principle of magnetic connector

Magnetic connectors usually consist of the following parts:

1. Magnet part: used for automatic adsorption connection to ensure that the two ends can be accurately aligned.

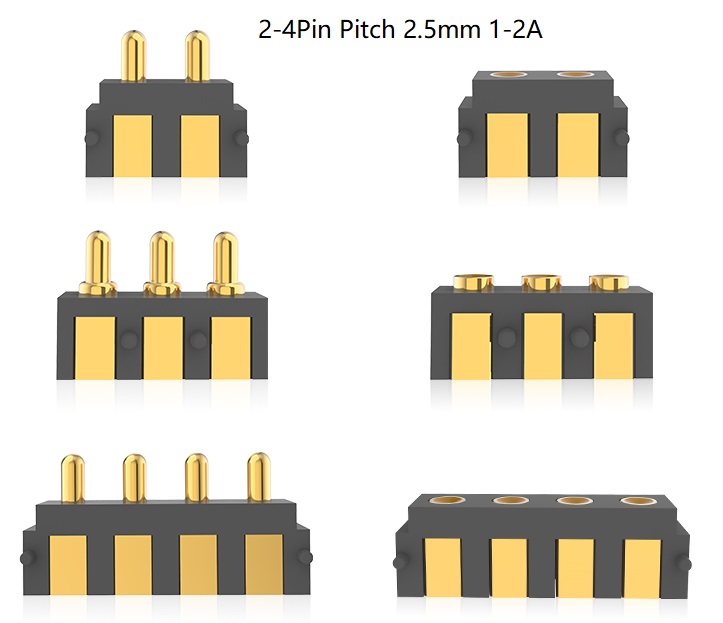

2. Contact point (shrapnel or Pogo Pin): to achieve the transmission of electrical signals or currents.

3. Shell or docking structure: plays the role of protection, alignment and stable connection.

Working principle:

One end of the magnetic connector has a permanent magnet, and the other end contains ferrous material or magnets with the same magnetic poles. When the two ends are close together, the magnetic force attracts them together; at the same time, the electrical connection is completed through elastic contact structures such as Pogo Pin. When disconnecting, just pull lightly, and it is not easy to damage the port.

2. Typical life range of magnetic connectors

1. Standard service life (mechanical life)

According to industry standards and product specifications of mainstream manufacturers, the mechanical plug-in life of magnetic connectors is usually:

10,000 times – 50,000 times

This means that under normal plug-in conditions, the connector can be used repeatedly for more than 10,000 times, or even up to 50,000 times.

2. Electrical life

The electrical life depends on the current, voltage and load conditions at each connection. Generally, the electrical life of a magnetic connector can be consistent with its mechanical life, especially in low-power devices. In high-power transmission scenarios (such as high-current charging), its electrical life may be reduced.

3. Factors affecting the life of magnetic suction connectors

1. Material and process

High-quality copper alloys, gold-plated layers and other conductive materials can significantly improve the connection stability and corrosion resistance;

The elastic fatigue of the spring and Pogo Pin is a key factor affecting the life;

High-quality magnets (such as NdFeB) have stronger suction and lasting magnetism, and are not easy to demagnetize.

2. Environmental conditions

Humidity, temperature, salt spray: High humidity and salt spray environments will cause corrosion on the contact surface and affect the connection effect;

Dust and metal debris: May enter the connector, interfere with electrical contact or damage the spring;

Vibration shock: Frequent mechanical shock will accelerate the loosening of contacts or aging of magnets.

3. Frequent use and operation mode

Frequent plugging and unplugging will accelerate wear, especially for the spring structure;

Rough plugging and unplugging may cause structural damage or poor contact;

Correct docking posture can effectively reduce mechanical pressure.

4. Electric load and arc corrosion

If there is an instantaneous high-voltage arc during the connection process, it will burn the contact point;

Especially in high-current transmission applications (such as electric vehicle charging), a reliable anti-arc design is required.

4. Life evaluation methods and standards

The evaluation of the life of magnetic suction connectors is mainly based on the following standards and test methods:

1. IEC 60512-5-2 (plug-in life test): Test the connector with a standard number of plug-in and unplugging times to detect its mechanical integrity and electrical performance changes.

2. Salt spray test (such as IEC 60068-2-11): Simulate the corrosion conditions at the seaside or in a humid environment.

3. Temperature and humidity cycle test: Test the reliability of the connector during high and low temperature conversion.

4. Electrical life test: Perform repeated connection tests at rated voltage and current to observe contact resistance, overheating, etc.

V. Life performance of magnetic connectors in various fields

1. Consumer electronics field

MacBook MagSafe interface: The official test life is more than 10,000 times, and some users have been able to maintain good connection after more than 5 years of use;

Smart bracelet/watch: The average life is about 10,000 times. Due to the relatively small number of charging times, it will generally not fail after 3 to 5 years of use;

Mobile phone data interface (magnetic suction): The life is 15,000 to 20,000 times under mild use conditions.

2. Medical equipment

Medical equipment requires high reliability, disinfection resistance, and corrosion resistance, and usually uses high-grade materials and sealing design. The lifespan standard is at least:

20,000 mechanical plugging and unplugging times

10 years or more electrical lifespan

3. Industrial and automation applications

High frequency of use, need to withstand vibration, temperature difference and oil pollution;

Industrial-grade magnetic connectors often set the lifespan standard to 30,000 to 50,000 times, using more durable materials.

VI. How to extend the service life of magnetic connectors?

1. Choose high-quality products

Choose a well-known brand with good craftsmanship and material guarantees;

Check the magnet suction force, Pin foot elasticity, and connection tightness.

2. Pay attention to environmental protection

Avoid environments such as moisture, salt spray, and chemical corrosion;

When using sealed magnetic connectors, the protection level can be enhanced (such as IP67 or above).

3. Keep clean

Regularly clean the dust and debris on the contact surface;

Avoid foreign matter from entering, which may affect adsorption and electrical contact.

4. Avoid overload

Do not exceed the rated voltage and current;

Add overvoltage protection or soft start circuit to reduce arc damage.

VII. Future development and trends

With the popularity of wireless charging and portable devices, magnetic connectors will become more intelligent and miniaturized. Future development directions include:

Self-cleaning contacts: Remove debris through magnetic design or elastic structure shaking;

Multi-function integration: Not limited to power transmission, but also includes signal transmission, data communication, and even optical transmission;

Higher life design: Extend the service life to more than 100,000 times through material innovation and intelligent circuit protection.

As a safe, efficient and convenient connection method, the life of magnetic connectors is generally 10,000 to 50,000 plug-in and pull-out times, which can meet the service life requirements of most consumer electronics and industrial applications. Its life is affected by multiple factors such as material technology, environmental factors, electrical load and usage. In the selection and use process, reasonable selection and maintenance are the key to ensure its long-term reliable operation.

Therefore, if it can be reasonably designed, used in a standardized manner and maintained regularly, the magnetic connector can maintain high stability and reliability throughout its life cycle, becoming an indispensable connection component in various devices.